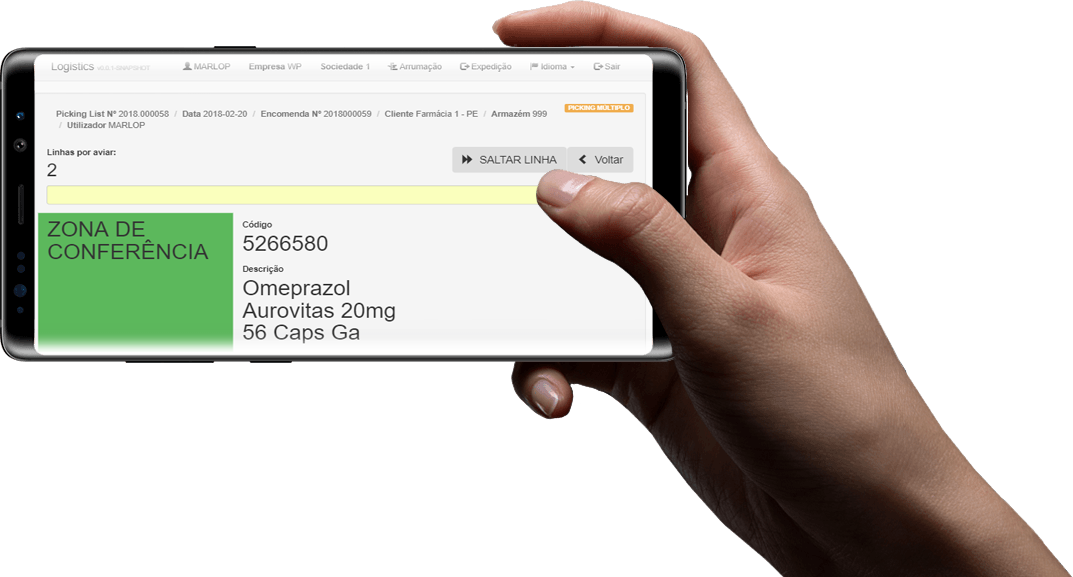

Technology, digitization, process automation. Flowinn‘s Logistics WMS solution transports your business into the future.

INCREASE YOUR COMPANY’S REVENUE

DECREASE OPERATING COSTS

The Logistics WMS application is subdivided into 5 modules: Reception, Storage, Shipping, Audit and Control.